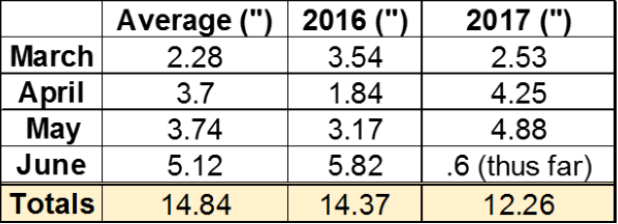

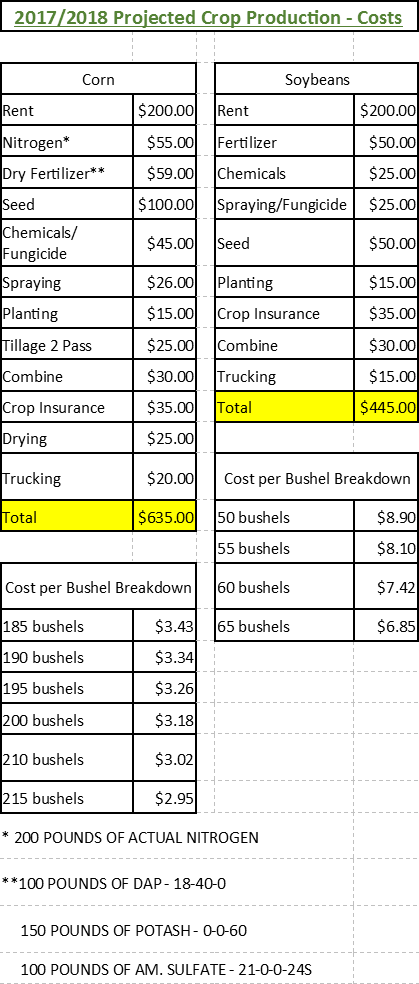

You may recognize this title from an article in last year’s newsletter where I talked about the various factors that determine nitrogen availability and need. Several customers who hired us to apply nitrogen with our 360 Y-drops saw significant results from placing the added nitrogen where the plants could find it at the time they needed it. Our adapt-N program gave us a good idea of what rates we needed to apply and we used our 360 Soilscan nitrogen tester to verify how much nitrogen was available from first application in the spring. The main takeaway from last years article was that every field had a different nitrogen need. Soil texture, tillage, planting date, nitrogen source, soil slope, and rainfall all contributed to the difference in nitrogen availability. If we had treated all fields the same using a base calculation of 1.1 lbs of nitrogen per bushel of corn, in some cases we would have spent dollars on inputs without a profitable response. However, in many cases if we had not added nitrogen where it was needed, the customer would have missed out on upwards to 40 bushel of corn.

Our Y-Drop application gives you the most efficient use of your nitrogen by minimizing the chance of nitrogen loss through better timing and placement of your nitrogen. Nitrogen loss from a spring UAN application over the top in pre-emerge corn can be 50% or higher, compared to less than 20% losses where customers used a split-pass approach with a combination of anhydrous, urea, and UAN. With tight margins between input costs and commodity prices the risk is too high to be guessing our nitrogen needs. Modern technology can give you accurate quantities of how much nitrogen is left in your field. Let us help you put this technology to use and ensure you don’t run short.

Andrew Tucker