A large part of the success of any great operation comes through trial and error. The famous story goes, Edison failed to refine the light bulb (one of the few creations he merely refined but did not invent) so many times it took him 10,000 attempts to perfect it. However rather than accepting failure 9,999 times he is quoted as answering questions on his failures as rather: ‘I have not failed. I have just found 9,999 ways that do not work’.

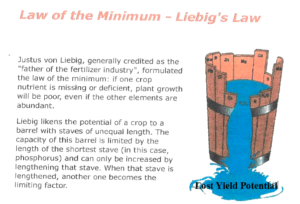

We have all seen tests and results shown to us by sales people that claim their products really work! Just because a product works on one area one year doesn’t mean it will work there or anywhere else on a different year. We also know that profit comes from having more bushels than expenses at the end of the year, so the question becomes what can we do differently this year to come out better than we have done in the past?

Every year I conduct multiple farm trials to learn how technology and products can benefit customers on their farms. Sometimes I see patterns and consistent results, and other times I don’t see much differences at all. The more trials I do, the more I learn. Technology has really helped gather useful information about these trials. With technology it’s simple to track the trials during the year and see yield differences at harvest.

Here are some of the trials we have going on this year: Nitrogen timing, rates, sources, and stabilizers; planting date trials; row spacing trials; weed control trials; fungicide trials; population trials; seed variety trials; tillage trials; seed treatment trials; and trials with microbial products. We have already learned a lot this spring from GPS trials comparing the WAAS, TerraStar, and RTK correction systems. Below are a few pictures of some trials we’re doing, and we look forward to sharing our results with you this fall. If you are interested in trying different products or farm practices on your operation, let us know and we can help you set up your own trials.

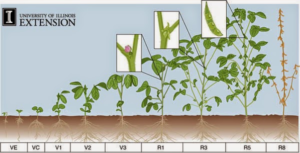

In this trial, we are using NK’s S20-T6 variety to compare how row spacing and weed competition affect canopy and yield. We will have weekly photos showing progress, and can already see that the plants are slightly farther along on the 30” rows than the 15” rows. The 30” row beans were out of the ground a day sooner than the 15” rows, as the 1.5” spacing between plants (150k pop) helped with emergence compared to having 3” spacing between plants on the 15” rows. The soybeans with the weed competition seem ok but the yield monitor will tell the true story.

This is a trial comparing fall custom applied anhydrous ammonia with spring sidedress urea. The whole field also received 45 lbs UAN with the pre-emerge herbicide program. We were able to track applications using the AgLeader InCommand 1200 monitor and will be measuring yield with that monitor in a 9500 combine.

Farmers don’t make mistakes, they just leave test areas…or so I’ve been told. We planted this row in our test plot without first priming the meter on the electric drive row unit, so we had several feet of row before corn came out. When we planted soybeans in our plot about a month later we went back and filled in that row, giving us a good trial of corn planted April 25th compared to the same hybrid planted May 23rd. We will find out how planting date affects yield and moisture this fall. Right now that corn is V4 and V8.

– Andrew Tucker